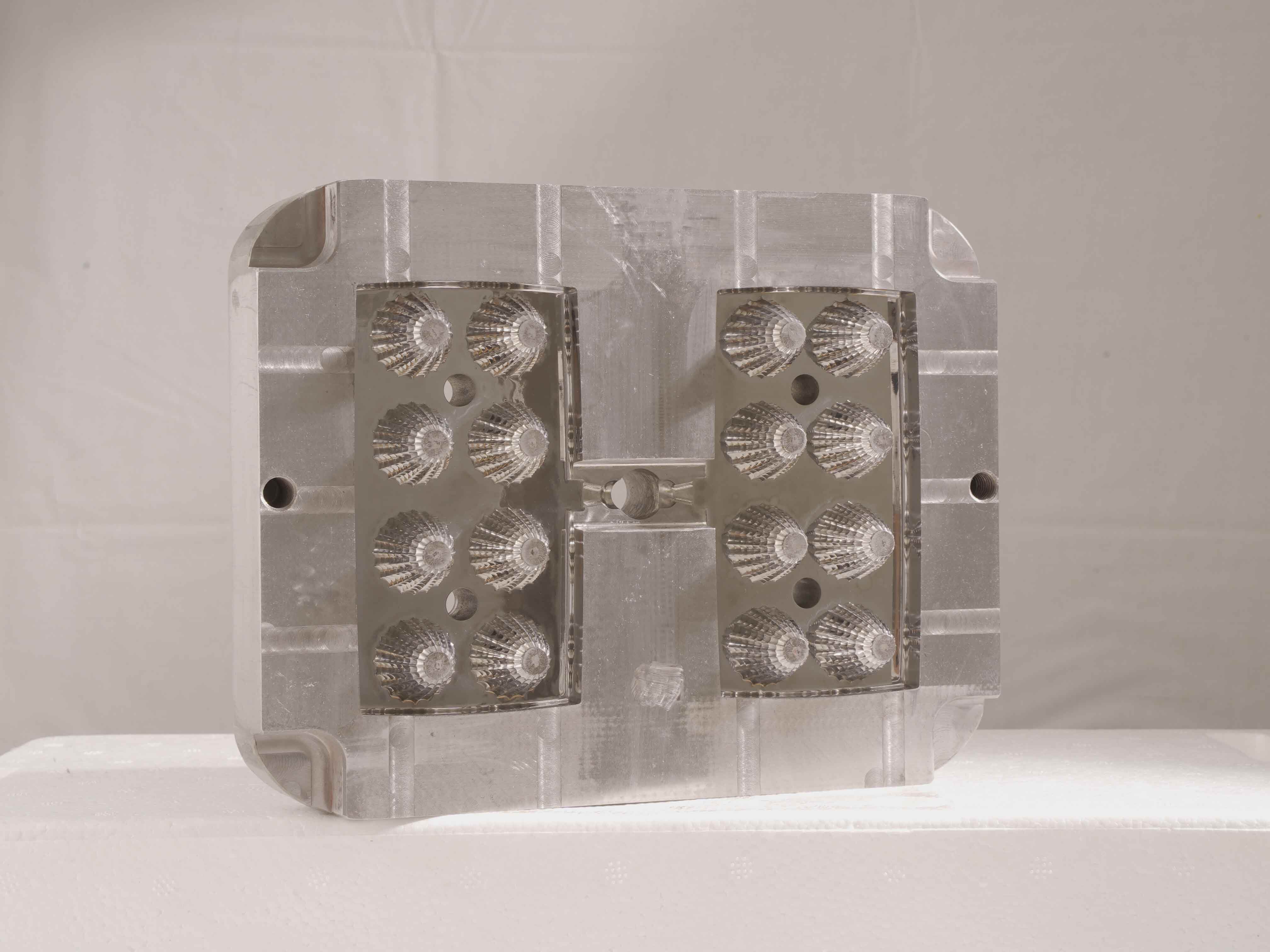

Foshan Geqin Auto Parts specializes in manufacturing precision molds for automotive headlight reflectors that meet stringent optical requirements. Our reflector molds are engineered to produce complex parabolic surfaces with surface accuracy within ±0.02mm, ensuring precise light beam patterns compliant with ECE/SAE regulations. The molds utilize premium tool steels (H13, P20) with specialized polishing treatments achieving optical-grade surface finishes (Ra <0.05μm). We incorporate advanced cooling channel designs that maintain uniform mold temperatures (±1°C) during production, critical for maintaining reflector dimensional stability. Our proprietary venting systems eliminate gas traps in deep-drawn reflector geometries, preventing flow marks and burn defects. The molds feature durable coatings (CrN, TiN) that extend tool life when processing high-temperature engineering plastics. We implement modular mold designs allowing quick changeover between different reflector configurations. Our quality control includes white light interferometry to verify optical surface profiles and coordinate measuring machine (CMM) inspection of critical dimensions. The molds are compatible with all standard injection molding machines (80-1000T) and can produce reflectors for halogen, HID, and LED lighting systems.