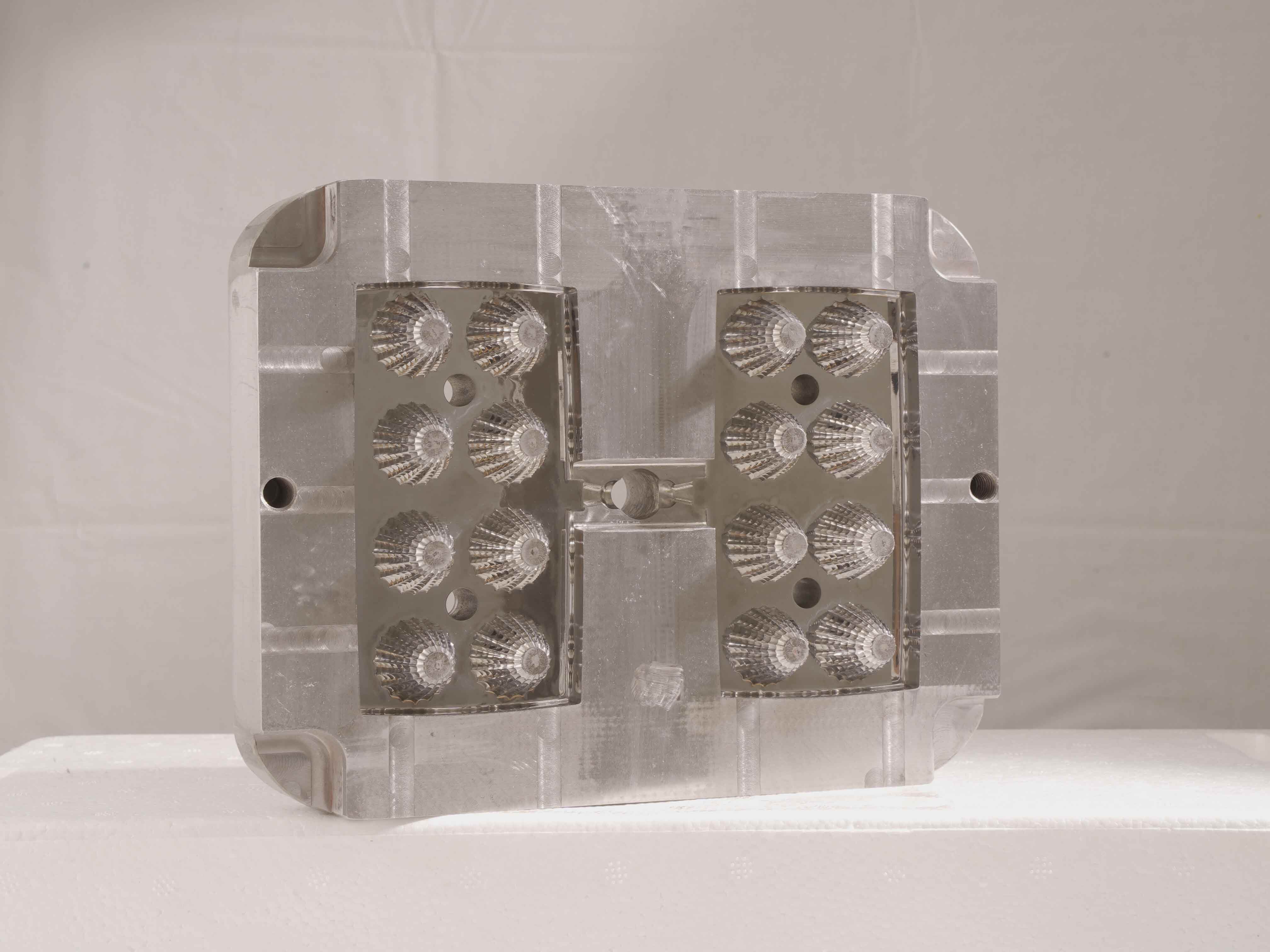

Our silver-plated reflectors for vehicle lighting represent the premium solution for maximum light output and beam control. The reflectors feature optical-grade polymer substrates with surface finishes optimized for metal deposition. Our proprietary silver plating process creates coatings with reflectivity exceeding 95%, significantly outperforming standard aluminum coatings. The plating system includes multiple intermediate layers that ensure excellent adhesion and long-term durability. We apply specialized protective coatings that prevent tarnishing while maintaining high reflectivity. The reflector designs incorporate precise optical geometries that maximize light collection and projection efficiency. Our manufacturing process maintains strict cleanliness standards to prevent defects in the reflective surface. The reflectors undergo comprehensive testing including salt spray exposure and thermal shock evaluations. We offer both vacuum metallization and electroplating options depending on application requirements. The designs account for thermal expansion characteristics to prevent distortion under operating temperatures. Our quality control process includes spectrophotometric analysis of reflectivity at multiple wavelength points. The reflectors are compatible with all major light source technologies including emerging LED and laser systems. We can develop custom solutions for specialized applications requiring unique beam patterns or form factors.